Classification of Jiangmen engineering plastics

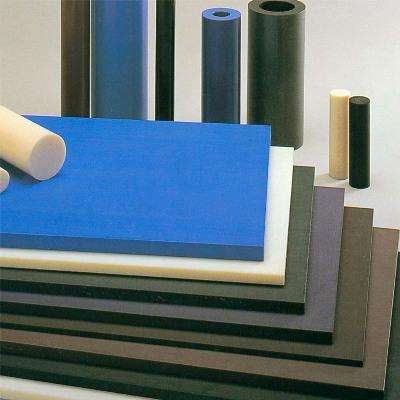

Classification of engineering plastics

There are many kinds of engineering plastics. At present, the common classification method is to distinguish them according to their output value and scope of application. They can be divided into general engineering plastics and special engineering plastics:

General engineering plastics: polyamide PA, polycarbonate PC, POM, polyphenylene oxide PPO, and pbtpet.

Special engineering plastics: fluoroplastics, polysulfone PSF, polyphenylene sulfide PPS, polyether ether ketone peek, polyimide PI, polyaryl par, polyphenylene Ekonol.

In addition, it can be classified according to chemical composition, heat resistance grade, crystallinity and the type of products after molding.

In many kinds of engineering plastics, most of the primary chains contain heteroatoms such as O, N and s. Therefore, it is clarified that most of the main chains composed of heteroatoms are the fundamental reason for endowing engineering plastics with characteristics.

Therefore, each kind of polymer data has its own application temperature range. The application temperature of general engineering plastics is generally 100-150 degrees, while that of special engineering plastics can be as high as 200 degrees (or higher). From the structural point of view, the temperature resistance is related to whether there is a ring structure in the main chain of the macromolecule or whether there is an atom (fluorine) with high electronegativity.

Characteristics of engineering plastics

Engineering plastics can be valued because of its rich raw material resources, superior functions and low prices. What is more important is that it has many properties that can not be compared with metals and other materials.

1. Low density, light weight and high specific strength. The relative density of engineering plastics is about 1.0-2.0, which is 1/8 of steel and 1/2 of aluminum Its specific tensile strength (tensile strength / density) can be as high as 1700-4000 (glass fiber reinforced engineering plastics), while that of steel is 1600 and that of aluminum is only 400.

2. Outstanding electrical insulation function.

3. Wear resistance, friction reduction and self lubrication.

4. Shock absorption, impact resistance and noise elimination.

5. Compared with metal materials, it is easy to process and form.

But engineering plastics also have its shortcomings. For example, the mechanical strength, hardness and thermal conductivity are not as good as metal; High temperature resistance is inferior to ceramics; Moreover, it has the characteristics of large water absorption, easy photochemical and creep. Therefore, engineering plastics, metals, ceramics, glass and other materials can complement each other in application, and give full play to their respective characteristics and interests.

Source: Jiangmen engineering plastics http://www.fcyou.com/

-

04-13

PVC Engineering Plastics: how PVC plastic pipes are formed

The forming process of PVC plastic pipes should start from the raw materials of PVC plastic granules, which can be divided into soft PVC and hard PVC according to the added amount of stabilizer, plast

-

11-12

What is the filling property of Jiangmen engineering plastics

What is the filling property of Jiangmen engineering plasticsIn recent years, PC modified plastics have developed rapidly in China, and its industrial system is gradually established and improved. Th

-

10-08

Jiangmen Engineering Plastics: how to classify Jiangmen engineering plastics?

How to classify Jiangmen engineering plastics? 1. Classification by application characteristicsAccording to the different application characteristics of famous plastics, plastics are usually divided

-

08-30

Application scope of PBT engineering plastics

PBT engineering plastics are widely used in electronics, car industry, office machinery and other fields. In Japan and the developed countries in Europe, PBT engineering plastics are mainly used in t