Selection principle and method of Jiangmen engineering plastics

Requirements for general structural parts: there are no special requirements for strength and heat resistance, which are generally used to replace steel and other materials. However, due to large batch, high production rate and low cost, sometimes there are requirements for appearance. Mainly used in: Car regulator and horn rear cover, motor cover, various external covers, cover plates, fasteners, etc. Primary data: high density polyethylene, polystyrene, polypropylene, etc. These data only bear low load and can be used at 60 ° ~ 80 °.

Corrosion resistant equipment and parts: it has outstanding corrosion resistance to acid, alkali, organic solvents and other chemicals, and also has certain strength. It is mainly used for: chemical containers, pipelines, valves, fans, etc., primary data; Polytetrafluoroethylene, perfluoroethylene propylene, etc.

Selection of common engineering plastics

Requirements for general structural parts: there are no special requirements for strength and heat resistance, which are generally used to replace steel and other materials. However, due to large batch, high production rate and low cost, sometimes there are requirements for appearance. Mainly used in: Car regulator and horn rear cover, motor cover, various external covers, cover plates, fasteners, etc. Primary data: high density polyethylene, polystyrene, polypropylene, etc. These data only bear low load and can be used at 60 ° ~ 80 °.

Transparent structural parts: in addition to the above requirements, it is necessary to have outstanding visibility, which is mainly used for; Transparent cover, oil standard, oil cup, optical lens, signal lamp, etc. Primary information: modified plexiglass, modified polystyrene, polycarbonate.

Wear resistant stressed transmission parts: they are required to have high strength, rigidity, durability, wear resistance, fatigue resistance, high thermal deformation temperature, and stable size. They are mainly used for bearings, gears, racks, etc. the primary data include: nylon, MC nylon, POM, and the application temperature can reach 80 ° ~ 120 °.

Antifriction self-lubricating parts: the requirements for mechanical strength are often not high, but the movement speed is high, so it is required to have low friction coefficient, excellent wear resistance and self-lubricating, which are mainly used for; Piston ring, mechanical dynamic seal ring, packing, bearing, etc. primary information: PTFE, polyoxymethylene filled with PTFE, low-pressure polyethylene shall be selected at low load and low speed.

High temperature resistant structural parts: in addition to the requirements for wear-resistant stressed transmission parts and wear reducing self-lubricating parts, it is also necessary to have high thermal deformation temperature and high temperature creep resistance. It is mainly used for structural transmission parts working at high temperature, such as car speed divider cover, bearing, gear, valve and sealing ring. Primary information: polyphenylene oxide, fluoroplastics, polyimide, and various glass fiber reinforced plastics, which can be more than 150 °.

Corrosion resistant equipment and parts: it has outstanding corrosion resistance to acid, alkali, organic solvents and other chemicals, and also has certain strength. It is mainly used for: chemical containers, pipelines, valves, fans, etc., primary data; Polytetrafluoroethylene, perfluoroethylene propylene, etc.

Engineering plastics can be used as engineering structure data and substitute metal to make machine parts. For example, polyamide, polycarbonate, polyformaldehyde, ABS resin, polytetrafluoroethylene, polyester, polysulfone, polyimide, etc. Engineering plastics have the characteristics of low density, high chemical stability, outstanding mechanical properties, superior electrical insulation, simple processing and molding. They are widely used in car, electrical appliance, chemical industry, machinery, instrument, appearance and other industries, as well as in aerospace, rocket, missile and other aspects.

Composition of plastics

The plastic we usually use is not a pure substance. It is made of many materials. Among them, high molecular polymer (or synthetic resin) is the primary component of plastics. In addition, in order to improve the performance of plastics, it is necessary to add various auxiliary materials in polymers, such as fillers, plasticizers, lubricants, stabilizers, colorants, etc., so as to become plastics with outstanding performance.

1. Synthetic resin

Synthetic resin is the most important component of plastics, and its content in plastics is generally 40% ~ 100%. Because the content is large and the nature of resin often determines the nature of plastic, people often regard resin as a synonym of plastic. For example, PVC resin and PVC plastic, phenolic resin and phenolic plastic are compared. Actually, resin and plastic are two different concepts. Resin is a kind of raw polymer, which is not only used to make plastics, but also used as raw material for coatings, adhesives and synthetic fibers. In addition to a small part of plastics containing 100% resin, the vast majority of plastics, in addition to the primary component resin, also need to participate in other substances.

2. Filler

Fillers, also known as fillers, can improve the strength and heat resistance of plastics and reduce costs. For example, the addition of wood powder in phenolic resin can greatly reduce the cost, make phenolic plastic one of the cheapest plastics, and significantly improve the mechanical strength together. Fillers can be divided into organic fillers and inorganic fillers. The former includes wood powder, rags, paper and various fabric fibers, while the latter includes glass fiber, diatomite, asbestos and carbon black.

3. Plasticizer

Plasticizers can increase the plasticity and softness of plastics, reduce brittleness, and make plastics easy to process and form. Plasticizers are generally high boiling point organic compounds that are miscible with resins, non-toxic, odorless, stable to light and heat. Phthalates are the most commonly used. For example, when producing PVC plastics, if more plasticizers are added, soft PVC plastics can be obtained; if no or less plasticizers are added (dosage < 10%), rigid PVC plastics can be obtained.

4. Stabilizer

In order to avoid the decomposition and damage of synthetic resin by the action of light and heat during processing and application, and to prolong the service life, it is necessary to add stabilizing agent in the molding process. Commonly used are stearate, epoxy resin, etc.

5. Colorant

Colorants can make plastics have various bright and beautiful colors. Organic dyes and inorganic pigments are commonly used as colorants.

6. Lubricant

The function of lubricant is to avoid the plastic from sticking to the metal mold during molding, and together, it can make the plastic appearance smooth and beautiful. Common lubricants include stearic acid and its calcium magnesium salts.

In addition to the above additives, plasticizer can also participate in flame retardant, foaming agent, antistatic agent, etc. to meet different application requirements.

Characteristics of plastics

1. Plastic has plasticity

As the name suggests, plastic is the material that can be molded. The so-called plasticity of plastic is that the solid plastic can be softened by heating, and then the softened plastic can be placed in the mold, so that it can be cooled and condensed into a certain shape of solid again. This property of plastics also has certain disadvantages, that is, it is easy to soften and deform when heated. Some plastics even deform when scalded with hot water, so plastic products are generally not suitable to contact with boiled water.

2. Plastic is elastic

Some plastics, like synthetic fibers, have certain elasticity. When it is stretched by an external force, the bent molecules will be straightened by flexibility, but once the tension is cancelled, it will return to the original bending state, which makes the plastic elastic, such as polyethylene and polyvinyl chloride film products. But some plastics are inelastic.

3. Plastic has high strength

Although plastic is not as hard as metal, it still has higher strength and wear resistance compared with glass, ceramics, wood, etc. Plastic can be made into strong gears and bearings on machines.

4. Plastic has corrosion resistance

Plastics do not rust in the humid air like metals, nor decay or be eroded by microorganisms like wood in the humid environment. Other plastics are resistant to acid and alkali corrosion. Therefore, plastics are often used as water supply and infusion pipes in chemical plants, doors and windows of buildings, etc.

5. Plastic has insulation

The molecular chains of plastics are combined by atoms with covalent bonds. The molecules can neither ionize nor transfer electrons in the structure, so plastics have insulation. Plastic can be used to make the sheath of electric wire, electric socket, shell of electric appliance, etc.

Source: Jiangmen engineering plastics http://www.fcyou.com/

-

04-13

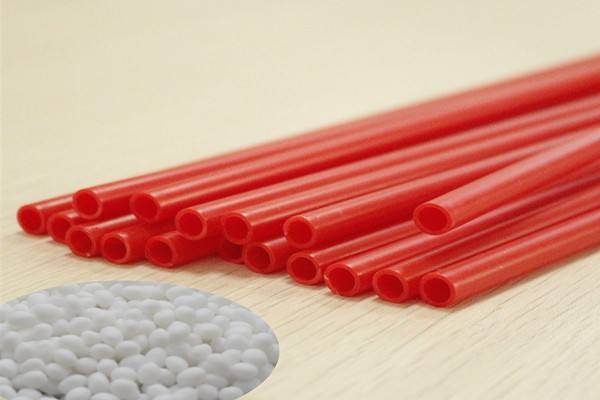

PVC Engineering Plastics: how PVC plastic pipes are formed

The forming process of PVC plastic pipes should start from the raw materials of PVC plastic granules, which can be divided into soft PVC and hard PVC according to the added amount of stabilizer, plast

-

11-12

What is the filling property of Jiangmen engineering plastics

What is the filling property of Jiangmen engineering plasticsIn recent years, PC modified plastics have developed rapidly in China, and its industrial system is gradually established and improved. Th

-

10-08

Jiangmen Engineering Plastics: how to classify Jiangmen engineering plastics?

How to classify Jiangmen engineering plastics? 1. Classification by application characteristicsAccording to the different application characteristics of famous plastics, plastics are usually divided

-

08-30

Application scope of PBT engineering plastics

PBT engineering plastics are widely used in electronics, car industry, office machinery and other fields. In Japan and the developed countries in Europe, PBT engineering plastics are mainly used in t